The origins of the metal building history date back nearly

100 years. Early in the 20th century, steel products companies began to appear.

Their products were generally agricultural – water troughs, feed bins, grain

bins, etc. These were mass-produced and traditionally of a single size.

Therefore, they could be “pre-fabricated” – a ready inventory to be delivered

when the customer needed it.

As time progressed, rudimentary building designs

began to emerge, such as the pre-fabricated garage. Again, this was a limited

product offering dimensionally, which allowed the garage to be carried in an

inventory.

During World War II, a need arose for structures

such as barracks and maintenance facilities that could be containerized and

shipped – ready to erect. This was a perfect outlet for steel products

companies. Buildings were produced that required no welding. They were

bolted-up, lending themselves to simple, quick construction as the war advances

and occupations unfolded.

By the end of the war, it was clear that the

industry would not return to its pre-war product offerings. Metal buildings

were here to stay. The post-war construction boom offered an ideal opportunity

to mass produce buildings for a variety of non-residential industries. Metal

building companies learned that partnerships with local contractors across a

region or even the entire country were an effective way to deliver an erected

building structure to the end customer.

Buildings during this time were still pre-fabricated

as the marketplace adapted to the limited, set sizes that were available.

However, structural engineers began to design more and more standard-size

offerings to meet demand and soon pre-fabrication was no longer possible. At

this time, still well before the computer age, the process came to be known as

the “pre-engineered” metal buildings industry.

This configuration continued from the 1950s on into

the mid-1980s. The advent of the computer to analyze and design structural

members quickly has ultimately led to the modern make-to-order process that

exists today. The pre-engineered system previously known is now limited to roof

and wall panels and some connections design.

Today,

the metal building industry boasts a capability of producing buildings for

virtually any low-rise, non-residential end use. These building designs are

performed quickly by industry engineers, who have vast knowledge of the

building codes utilized in the United States. The custom design practice allows

for economy in building design that makes metal buildings very attractive to

the marketplace.

PEB –

Features & Advantages

Features and

Advantages

Features:

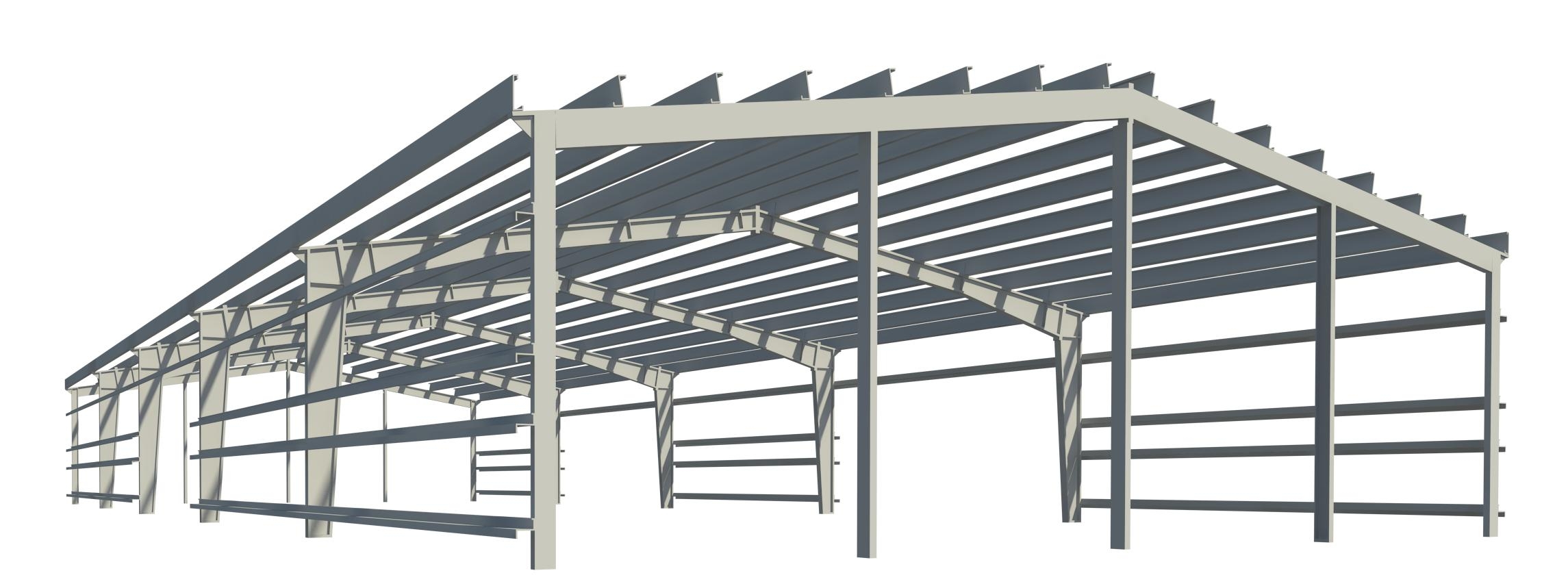

Pre-engineered steel buildings use a combination of built-up

sections, hot rolled sections and cold formed elements which provide the basic

steel frame work with a choice of single skin sheeting with added insulation or

insulated sandwich panels for roofing and wall cladding. The concept is

designed to provide a complete building envelope system which is airtight,

energy efficient, optimum in weight and cost and, above all, designed to fit

user requirement like a well fitted glove.

Pre engineered steel buildings can be fitted with different

structural accessories including mezzanine floors, canopies, fascias, interior

partitions etc. and the building is made water proof by use of special mastic

beads, filler strips and trims. This is very versatile buildings systems and

can be finished internally to serve any functions and accessorized externally

to achieve attractive and unique designing styles. It is very advantageous over

the conventional buildings and is really helpful in the low rise building

design.

Pre engineered buildings are generally low rise buildings

however the maximum eave height can go up to 25 to 30 meters. Low rise

buildings are ideal for offices, houses, showrooms, shop fronts etc. The

application of pre engineered buildings concept to low raise buildings is very

economical and speedy. Buildings can be constructed in less than half the

normal time especially when complemented with the other engineered sub systems.

The most common and economical type of low rise buildings is

a building with ground floor and two intermediate floor plus roof. The roof of

low rise buildings may be flat or sloped. Intermediate floors of low rise

buildings are made of mezzanine systems. Single storied houses for living take

minimum time for construction and can be built in any type of geographic

allocation like extreme cold hilly areas, high rain prone areas, plain land

obviously and extreme hot climatic zones as well.

Advantages:

Reduction in Construction Time: Buildings are typically

delivered in just a few weeks after approval of drawings. Foundation and anchor

bolts are cast parallel with finished, ready for the site bolting. In India the

use of PEB will reduce total construction time of the project by atleast 50%.

This also allows faster occupancy and earlier realization of revenue.

Lower Cost: Due

to the systems approach, there is a significant saving in design, manufacturing

and on site erection cost. The secondary members and cladding nest together

reducing transportation cost.

Flexibility

of Expansion: Buildings can be easily expanded in length by adding

additional bays. Also expansion in width and height is possible by pre

designing for future expansion. Larger Spans: Buildings can be supplied to

around 80M clear spans.

Quality

Control: As buildings are manufactured completely in the factory

under controlled conditions the quality is assured.

Low

Maintenance: Buildings are supplied with high quality paint systems

for cladding and steel to suit ambient conditions at the site, which results in

long durability and low maintenance costs.

Energy

Efficient Roofing and Wall Systems: Buildings can be supplied with

polyurethane insulated panels or fiberglass blankets insulation to achieve

required U values.

Architectural

Versatility: Building can be supplied with various types of fascias,

canopies, and curved eaves and are designed to receive pre cast concrete wall

panels, curtain walls, block walls and other wall systems.

Single

Source Availability: As the complete building package is supplied by

a single vendor, compatibility of all the building components and accessories

is assured. This is one of the major benefits of the pre engineered building

systems.

Benefits of

PEB:

Pre-engineered building systems provide real value to clients

without sacrificing durability, seismic and wind resistance, or aesthetic

appearance. Cost savings begin right at the drawing preparation stage. Systems

engineering and fabrication methods help reduce interim financing costs through

faster construction and minimized field erection expense. An added benefit is

earlier occupancy of the facility and a head start on day-to-day operations by

the client.

Apart from costs, there is an assurance of factory-built

quality and uniformity in design and fabrication. These systems are also energy

efficient; incorporate watertight roofing systems; enable easy disassembly or

future expansion and have the lowest life cycle maintenance costs. Adding to

these; there is no mess of sand and cement; power savings; walk able ceilings;

progressive and non-progressive panel systems for walls. A poor man can be

provided with a home created under strict quality control and having a longer

life span, with greater safety against natural disasters like earthquakes and

cyclones.

Moreover, it is possible to create the building in required

form and shape. And the ‘system approach’ renders a holistic way of thinking at

one platform for consultants, designers, architects, and builders. Thus it

tends to achieve a perfect harmony among various stringent specifications and

aesthetic requirements in a most economic way. In nutshell, the benefits may be

summarized as under

• Easy future expansion/modification.

• Weather proof and fire hazards.

• Optimized design of steel reducing

weight.

• International Quality Standards

• Seismic & Wind pressure resistant.

• Quality design, manufacturing and

erection, saving around 30-40% of project time

• Quick delivery and quick turn-key

construction.

• Pre-Painted and has low maintenance

requirement.

• Erection of the building is fast.

• The building can be dismantled and

relocated easily.

• Future extensions can be easily accommodated

without much hassle.

• Increased Life cycle performance and cost

competitiveness

• Environment friendly structures

• Better rainwater harvesting through

gutters and down-take arrangements

• Lighter weight; savings in foundation

cost of 10-20 percent

• The building can be dismantled and

relocated easily

• Easy integration of all construction

materials

• Energy efficient roof and wall system

using insulations.

• Suitability for Hilly regions and other

geographically difficult areas

• Unlimited architectural possibilities

Robin Thomas